You are currently browsing the category archive for the ‘Chemistry’ category.

A few thoughts on struggle in learning. I’ll confess to having taught undergraduates in the classroom and the research lab environment. My classroom teaching bona fides are limited to 6 years of college level chemistry lecture/lab and quite a bit of one-on-one chemistry tutoring.

Many students approach college chemistry courses with caution. For some, a year of freshman general chemistry is mandatory for their major. Majors such as pre-med, physical therapy, and veterinary medicine require organic chemistry in addition to general chemistry. As my specialty lies in organic chemistry, I have experience teaching both general and organic chemistry students..

From my perspective, general chemistry is as much a mathematics course as it is a science course for many first-year students. A significant portion of general chemistry involves establishing and solving problems that necessitate fundamental algebraic manipulations and calculations. Skills such as balancing equations, maintaining units throughout calculations, and understanding significant figures are essential to master. Additionally, there is the challenge of learning the new vocabulary.

Students who managed to avoid chemistry in high school sometimes found themselves treading water in college chemistry and were afraid of taking two 5 credit hour hits to their GPAs. Most pushed on and got through it. General chemistry is a foundation course and is critical for further pursuits in fields related to the use of chemicals. Unfortunately, a year of gen chem doesn’t really make a person able to function as an independent chemist. It is helpful, though, for technicians in a lab doing routine chemical tests.

Gen chem is to chemistry as The Hobbit is to The Lord of the Rings– it is the necessary prelude to a larger story.

A common problem I encountered while teaching chemistry was the desire of some students to give up hope of ever “getting it”. They would hold off attending office hours to discuss their difficulties until it was too far down the semester timeline. This was usually after a few botched regular exams or a low midterm grade. Frequently the struggling student was having trouble with or neglecting the assigned homework from the text.

Now and then you’d run into a prof who had performance expectations that even they might not have met as an undergrad. They’ll strut around acting as though they were singlehandedly maintaining “proper” academic ideals. Who knows, maybe they had a point. You can try to enthuse everyone using words and pictures, but inevitably there are those who are utterly disinterested, inept or just anxious to put chemistry behind them.

In retrospect, I should have been more direct in calling in more students to office hours who were in grade trouble early in the term. Unfortunately, like many other profs I sometimes subscribed to the sink or swim approach to college education where unsuitable students are culled from the herd. It is a sort of Darwinistic mindset that is easy to fall into. In the end, we have to give all students a fair chance or even a second chance to earn the credentials that the institution confers.

Colleges are organizations that award credentials to verify achievement in meeting or exceeding educational standards set by in-house professors. It tells people that you completed what you started: you navigated a complex maze of intellectual achievements and came out the other side a success.

For any given subject there are always those who struggle with it to some extent. It could be from simple boredom, distractions from real life or the comprehending of difficult material. It may be that the subject just isn’t for them. For myself, I struggled with a foreign language and eventually gave up. I needed full immersion and that wasn’t going to happen. I still regret giving up.

One problem that can often be addressed, however, is the matter of struggle. It seems that many students are not accustomed to struggling with learning. All of us have learned particular subjects successfully because it “just fit” our cognitive abilities, interest or perhaps it was brilliantly presented to us. Or it was a special time in our lives when we were uniquely receptive. It could very well be that previous exposure to the subject was a bit shallow with grade inflation, leading to overestimation of their abilities.

Unfortunately for some, the very necessity of struggle convinces them that the subject is beyond their abilities. They come to believe that if the subject does not immediately stick or appear obvious, then they might as well give up because they will never “get it” along with a collapse of self-esteem.

Giving up on a subject early-on could allow them to switch directions in their education with less time lost and perhaps they would be relieved by that. In this case, giving up is just making a better choice based on experience. Regardless, students should be unburdened early on of the idea that struggle is a predictor of failure. In reality, most learning involves struggle at least to some extent.

Remedies for Struggle

Reading the assigned chapters several times is helpful. First pass, scan the content for a general idea of where the topic is going. A careful reading next with a focus on the example problems is very helpful. Try to understand the example problems and the reasoning presented. Next work on the problem set. If there is time, a third reading can help to cement in the concepts in the chapter. Before going on, work on the assigned problems. Open the solutions manual only if stuck. Struggle with the problem a bit. Success with solving assigned problems can be extremely helpful for a student.

If laboring alone isn’t helping, some schools have tutoring resources available. If not, there are often tutors who will charge on an hourly basis. A few hours of tutoring may be all it takes to get back on track. Sometimes there may be study partners from your class who can study with you. Then again, office hours with your prof or TA can help you over some rough spots. The point is- Struggle!

When I was writing exams, I would look at the example problems in the text as well as the assigned problems. I chose the problems to assign because I felt that they got to the heart of the concepts I held as important to the subject at the level of the content. I would use the assigned problems or those from lecture to write problems using different substances where a reaction would lead to an unambiguous answer. It’s ok to write some questions that require bit of logic to solve, but you can’t turn the exam into an intelligence test.

I once taught a course in chemistry for non-majors. These were students who had tried to get into Geology for Poets or Astronomy but couldn’t get in. They were trapped into taking chemistry for their science requirement for graduation! Early on, a few “representatives” of the class cornered me after a lecture and informed me that “everyone” expected true/false questions on the exams. Pausing, I said I would give them true/false questions, but they would get 1 point for a correct answer, 0 points for no answer, and -1 point for an incorrect answer. The lesson was that if you don’t know something it might be better to just be quiet. After a single exam they never mentioned true/false questions again.

Students eventually realize that chemistry is a highly vertical subject. The more advanced and interesting concepts are built upon or knitted together from those learned earlier. Later coursework will assume that the student has a grasp of content from earlier prerequisite courses. Thirty-one years later the 95 course evaluations from that Catholic women’s college still sit in an unopened envelope in my office.

Find a way to deal with anxiety. Exercise or find a councilor, psychologist, or psychiatrist for help. Anxiety is “druggable”, that is there are meds for it that are very effective. I’m sure there are exceptions, but a family practice doc can’t go very far down the road in treating anxiety. A psychiatrist can fine tune and mix the individual meds to best suit you. It really works.

Most importantly, the student should not EVER get behind in the coursework. It might even be better to drop the class than try to make up for much lost time. The normal rate of chemistry content flow to be absorbed is already high. To have to make up for time lost while also keeping up with the current content flow is often impossible.

Finally, consider that struggle just means that you have to put forth effort to learn. True learning means that your neurons are making new connections in your brain, not just images of something new. To have learned means that your brain has found a way to take diverse inputs and assemble them into part of your consciousness. Sometimes it isn’t easy, but persistence is the key.

Note: What follows are my observations and information from my oncologists and what is scraped off the interwebs. I try to seek information from either primary research literature, medical textbooks or from credible secondary sources. For treatment, I stick to a university medical institution and medical school faculty managing my treatment. I tend not to believe in dietary or nutraceutical approaches. It has been my observation that the origins of cancer are biochemically different from curative or preventative biochemistry. In other words, preventative measures by diet or supplements are mechanistically distinct from the treatment of cancer cells. Divine intervention is not testable, driven by faithful wishing and is supported only by anecdote. I believe that if something truly happens in the universe, it will have an observable mechanism and therefore be measurable.

Oh yes, if you’re squeamish with talking about your prostate because it’s part of your reproductive apparatus, get over it. Part of successfully living with cancer is being able to talk about and learning from it. I’d rather die at least knowing about it.

Because of modern medicine, my experience with both throat and prostate cancer has not been a rocket sled ride to the hereafter. It’s been said that some cancers can be thought of as a treatable, chronic condition and for me that has been true thus far. As luck would have it, my throat cancer was viral in origin and consequently highly treatable by IMRT irradiation and cisplatin. Since 2013 I have had yearly checkups that have all indicated no visible return of the cancer. Since I go to a university medical center, I have had medical students and various head and neck residents also peering down my throat from a camera threaded through my nose picturing my gullet in all of its pink glistening majesty.

The prostate story is a bit different. Before diagnosis the cells had already left the prostate (stage 4) and were judged to be Gleason 9 by histopathology. This was unfortunate. Outside of the prostate capsule they began to wander around through the lymphatic system, lodging in the lymph nodes. Since there was no unified target for surgery or concentrated radiation, The cutters were not called in. Elvis had left the building. After IMRT radiation of the prostate, seminal vesicles and suspected nearby lymph nodes along with 2 years of hormone ablation, my PSA returned to 0.01 ng/mL. Things had taken a turn for the better.

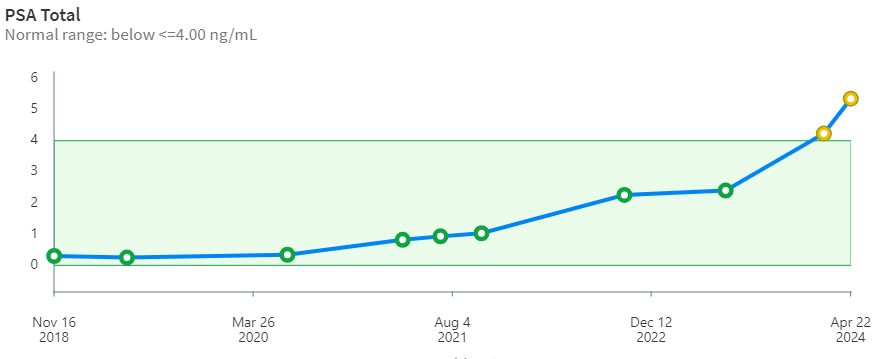

But, the other shoe had to drop eventually. After 9 years, my stage 4 prostate cancer has begun to ramp up steeply. The PSA curve over time (below) is looking more and more like a hockey stick. The borderline PSA value for treatment is 4.00 ng/mL. When it pops up over that value the oncologists begin to take notice. Whether this is based on some statistical mortality data or because of what insurance companies will likely cover is unclear to me. Importantly, PSA may also indicate non-cancerous conditions like prostatitis and benign prostatic hyperplasia. PSA is only an indicator and alone is not definitive. Biopsy is needed to verify and grade the tissue. Of this whole adventure, the biopsy was the worst of it for me. During the procedure, the urologist asked questions about my hobbies -his was carpentry- but I was too distracted to talk about airplanes.

Stage 4 is indicated by histology and backed up by the PET scan revealing radioactive (avid) spots outside of the prostate. Thankfully, this time around nothing was found in the head & neck, chest, prostate or bones. That was good news.

However, the PET/CT scan did show the presence of 5 or so avid lymph glands along the aorta from below the chest to above the prostate.

A proper prostate cancer diagnosis requires more than just a PSA value. An abnormal prostate is detected by digital examination by a urologist and the presence of cancer cells is confirmed by biopsy by a histologist.

But, wait a minute. Exactly what is PSA and what does it do? According to Wikipedia, Prostate Specific Antigen (PSA) is a peptidase enzyme (a protein) secreted by the epithelial cells of the prostate gland. It’s immediate job is to liquify the semen in the seminal coagulum, allowing sperm to swim freely. It is also thought to be involved in dissolving cervical mucus, allowing sperm to enter the uterus. Amounts of PSA above a certain threshold are not normally found in the blood. Elevated PSA is associated with prostate cancer. It’s just a marker.

Serine protease enzymes like PSA have a serine amino acid in the active site of the enzyme which is capable of connecting temporarily with a carbonyl carbon of a (C=O) peptide bond. Since proteins are long chains of peptide bonds, cleaving a peptide bond snips the protein into smaller pieces.

Chemists are all about the mechanisms of chemical transformations and the following has been proposed for a serine protease.

All this said, it turns out that when castration resistance sets in, things begin take a turn for the worse. Prostate cancer cells begin to accumulate in the bone marrow, they begin to interact and develop into tumors that are essentially beyond the reach of treatment. The spine is a common place for them to go, but they can spread to other organs as well.

Of particular interest is the spread of prostate cancer to bone. Prostate cancer cells have an affinity for bone marrow tissue. In my case, the PET/CT scans gave no indication of being present in the head & neck, the chest or bones. That’s good news. In my first round of treatment, I was given 18F-Glucose diagnostic for the PET scan. This time I was given the more receptor-selective 18F PSMA diagnostic called Pylarify. While it is selective for a particular receptor on the cancer cell, it also shows up elsewhere in the body in the PET scan as a result of circulation and transport out of the system. Receptor-specific drugs will bind to the intended receptor, but only after they wander around and stumble into it. This is made less than random due to active transport or solubility partitioning. The effectiveness also benefits by resistance to metabolism and excretion.

Pylarify is a kind of pseudo-peptide containing two modified amino acids, lysine and glutamic acid, joined at the nitrogen atoms as a urea linkage. The key step is the nucleophilic aromatic substitution of trimethylammonium by 18F on the pyridine ring. The presence of abundant heteroatoms (nitrogen and oxygen) groups is not uncommon for pharmaceuticals and is absolutely ordinary for proteins. Heteroatoms serve as hydrogen bond donors and acceptors which is critical in biochemical transformations. A hydrogen bond donor can reversibly bind to a hydrogen bond acceptor and keep the molecules in close proximity long enough for a transformation as well as participate in it.

Pages 29-51, ISSN 0969-8051, https://doi.org/10.1016/j.nucmedbio.2021.12.005.

The interaction of prostate cancer cells in the bone marrow environment is fairly complex and is well described by Zhang X. Interactions between cancer cells and bone microenvironment promote bone metastasis in prostate cancer. Cancer Commun (Lond). 2019 Nov 21;39(1):76. doi: 10.1186/s40880-019-0425-1. PMID: 31753020; PMCID: PMC6873445.

The interaction of prostate cancer cells with bone marrow cells is a topic for another day.

Prologue: What follows is a look at the use of 68Gallium as part of a positron emitting radioligand from an organometallic chemist’s point of view. I’m not from nuclear medicine nor am I a radiation oncologist.

It had to happen … the other shoe has dropped. My stage-4 prostate cancer has come charging back for round 2 after 9 years. Again, I’ve taken a personal interest in radiation oncology. Recently, my PSA shot up steeply through the 4.0 ng/dL threshold triggering an appointment with my radiation oncologist who has ordered a PET/CT scan. Back in 2015 I finished 18 months of hormone ablation (chemical castration) and got the PSA from 29 down to 0.01 with Lupron injections and earlier, a large cumulative dose of x-radiation in the lower abdomen. I have to say that while I experienced no discomfort at all in this round of treatment, I did lose body hair and muscle mass.

PET/CT scanning is an important tool in locating prostate cancer cells. Riding the platform in and out of the scanner is expensive but important. Unfortunately for me, the CT contrast agent is a potent emetic so the scanner becomes an expensive vomitorium ride.

The story of PET, Positron Emission Tomography, has evolved over decades of advancement. To begin, tomography, detectors and computers had to be invented. Separately, positron emission as a medically viable radiation source had to be identified and validated. A substrate for selective delivery of the isotope must be found. In the case of 18Fluorine, it is available as an organofluorine molecule like 18F-Glucose. It turns out that the 18F-Glucose concentrates in clinically useful places and K18F does not.

Positron Emitters

Atomic nuclei that are deficient in neutrons can have an instability leading to emission of a positron (anti-electron with a + charge), also called a β+ decay, which lessens the neutron deficiency by ejecting a positive charge from the nucleus. When a positron is ejected from the nucleus it finds itself immediately swarmed by the electron clouds of surrounding atoms and molecules and doesn’t travel very far. When a positron encounters a negatron (regular electron, β−), they annihilate one another and emit two gamma photons of 511 keV energy at 180 degrees apart. This is a mass to energy conversion. Loss of one positive charge from the nucleus gives rise to a transmutation of the atom causing a one-unit drop in atomic number, that is it goes from n+ to (n – 1)+, but retains most of its atomic weight. In this case, 6831Gallium undergoes positron decay to 6830Zinc.

Positron emitters include 11Carbon (T1⁄2 = 20.4 min), 13nitrogen (T1⁄2 = 10 min), 15oxygen (T1⁄2 = 2 min), 18fluorine (T1⁄2 = 110 min), 64copper, 68gallium, 78bromine, 82rubidium, 86yttrium, 89zirconium, 22sodium, 26aluminium, 40potassium, 83strontium, and 124iodine. This a list given by Wikipedia, but there are many more in more comprehensive tables.

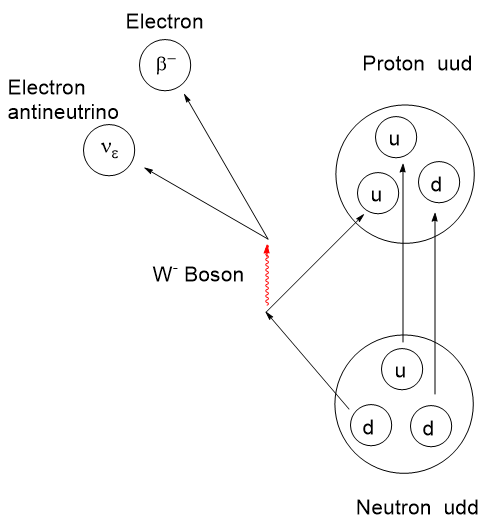

The actual mechanism of β-type emission requires a venture into fundamental particles called quarks. Protons and neutrons are composite particles called hadrons, not fundamental particles. Protons and neutrons are each comprised of 3 quarks, but with a different combination of “up and down flavors” where flavor refers to the species of quark. There are 6 flavors of quarks: up, down, charm, strange, top, and bottom. Interconversion between protons and neutrons can occur if one of the 3 top or bottom quarks changes flavor. By all means, if this interests you, take a dive into it. I shall stop here.

Positron emitters tend to have a short radioactive half-life as well as a limited chemical half-life in the body before they are cleared out through the kidneys or other routes. Ideally, the goal is to deliver a high radiation dose selectively to a target tissue as fast as is safe then disappear. Prolonged irradiation to surrounding tissue is undesirable. The optimal radiopharmaceutical will be highly target selective and have a short half-life. A selective radiopharmaceutical is one that will accumulate in a desired cell type or organ. Accumulation can be aided through simple solubility, the ability to undergo transport through a cell wall, affinity to a specific receptor and the ability to function fast enough to resist the various clearance mechanisms.

A short half-life means that the radioactivity per gram of radioisotope, specific activity in Becquerels per gram, will be at its maximum after activation. Though the radioactivity may be intense, the radiation dose can be controlled by the amount of mass administered. With radioisotopes, there are two kinds of purity to consider: Chemical purity referring to the atoms and molecules present; Radiological purity referring to the presence or absence of other radioactive isotopes. To provide maximum safety and effectiveness, the specific radioisotope with the desired decay mode should be the only source present. If your desired source is an alpha emitter, you don’t need spurious quantities of a gamma emitter present because of inadequate purification.

Economical methods of preparing positron emitters had to be addressed. To fully exploit PET for any given situation, tissue selectivity of radioligands had to be determined and selective positron radiopharmaceuticals developed. Due to the short half-life of these radioisotopes, rapid and safe methodologies to produce them by efficient nuclear transformations, isotope isolation followed by chemical synthesis had to be developed. It is important that isotope generation, isolation and attachment to a ligand be done nearby the hospital for the proper activity to reach the patient.

Positron emitter production involves a nuclear reactor for neutron activation or a cyclotron accelerating protons or deuterons in the preparation. Because both of these sources are highly destructive to organic molecules, an inorganic radioisotope is produced separately and chemically modified to produce an inorganic species that can be chelated or otherwise attached to a radiopharmaceutical. This technique evolved from simple radiography in the 1930’s to a large array of techniques and applications today. The reader is invited to take a dive into this topic.

Since my cancer experience began, a few new radiotherapies and imaging agents have landed in oncology space for prostate cancer. Recently I posted on Pluvicto PSMA (Prostate Specific Membrane Antigen) which was before I knew about my current prostate situation. PSMA is a transmembrane protein present in prostatic cells. Pluvicto uses a chelated 177Lutetium beta emitter as the destructive warhead and a peptidomimetic fragment for binding to the PSMA receptor.

A Brief Interlude into Quality Factor

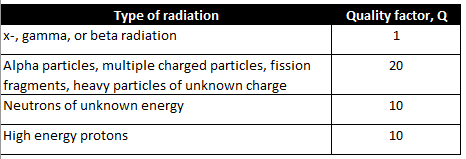

It should be noted that the various forms of particle (alpha, beta, or neutron) or electromagnetic radiation (x-ray or gamma) have differing abilities to penetrate and cause ionization of within matter. There is a factor for this which is used to refine dosage calculations. It is called the Quality factor, Q.

The destructive effects of radiation stem from its ability to ionize matter along its path. Ionization is a disruptive effect that may result in fragmentation of molecules or crystal lattices into reactive positive or negative ions. Single electron radical species may be formed as well. It is possible for some fraction of the disrupted molecules to recombine if the fragments haven’t already diffused away or gone on to further transformations.

The deleterious effects of radiation on living tissue stems from the amount of disruptive energy transferred to tissues along the path of each particle. Charged particles like electrons, protons and alpha particles tend to dump their energy into matter rapidly and along a short path making them less penetrating than neutrons or electromagnetic rays in general.

Quality factor, Q, is a dimensionless coefficient that is multiplied by an absorbed dose to give a more realistic estimation of radiation energy absorption. Interestingly, the Q for neutrons varies with energy and rises to a maximum around 0.5 to 1 MeV of energy and falls off at higher energies.

The larger the Q factor, the larger the corrected radiation effect. X-, gamma, and beta radiation have a Q factor lower than the others by a factor of 10 to 20. The x- and gamma rays will tend to pass through matter leaving a small amount of their energy to disruption. In radiation therapy this is compensated for by just increasing the fluence or the exposure time.

For clarity, x-rays are generated from the electron cloud around an atom via electron transitions. For instance, if an electron is dislodged from an inner, low energy orbital, another electron can occupy that vacancy by the emission of an x-ray. Gamma rays originate from nuclear energy transitions. Often a nuclear decay might result in a new nucleus that is not at its ground state and would be categorized as metastable. This metastable state, which has its own half-life, can collapse to its ground state by the emission of a gamma ray matching the loss of energy by the nucleus.

Neutrons

Free neutrons are special. They undergo beta decay with a short half-life outside the nucleus having t1/2 = ~ 10-15 minutes, depending on the information source. Not having a charge, they tend to be more penetrating than other particles. However, effective shielding can be had with a hydrocarbon like paraffin or water by virtue of the high concentration of hydrogen nuclei present in these substances. Neutrons are not affected by charge repulsion from an atomic nucleus and therefore can collide and interact with the hydrogen nucleus (a proton). They can scatter from hydrogen nuclei, leaving behind some of their kinetic energy with each collision (see “Neutron Lethargy“). This scattering is the basis for using water to moderate the neutrons in a nuclear reactor. Neutrons are cooled by repeated collisions with hydrogens in water to the point where their kinetic energy of 0.025 eV, which from the Maxwell-Boltzmann distribution corresponds to a temperature of 17 oC, thus the term “thermal neutrons“.

Many elements absorb neutrons, increasing the atomic weight and very often altering the stability of the nucleus leading to a radioactive decay cascade. This is what is happening in neutron activation. In the case of water, the ability of free neutrons to collide with hydrogen nuclei allows them to dislodge hydrogen ions or free radicals from organic and biomolecules resulting in ionization and makes them quite hazardous to living things.

Radioligands

Drugs like Pluvicto are referred to as a radioligand. There is a radioisotope connected to an organic “ligand” for selective binding to a specific protein receptor. A radioligand is injected and diffuses its way a particular receptor where it binds. As it turns out, due to the gamma radiation also emitted by 177Lu, Pluvicto is a radioligand that can also be located in the body by the gamma radiation it emits. In general, a radioligand can be used for two endpoints: To find and signal the location of a particular cell type; and to find and vigorously irradiate a particular cell type.

There are recent radioligand compounds that are used as PET (Positron Emission Tomography) diagnostic agents which selectively bind to the PSMA receptor where they can undergo positron emission revealing the site of prostate cancer cells by tomography. 18F-glucose was first synthesized in 1967 in Czechoslovakia at Charles University by Dr. Josef Pacák and was first tested as a radiotracer by Abass Alavi in 1976 at the University of Pennsylvania on volunteers. Positron tomography came along later. Cancer cells consume glucose faster than normal cells so the 18F will tend to accumulate to a slightly greater extent and reveal their position by positron annihilation. The two 511 keV x-rays simultaneously detected at 180o apart are identified by a ring coincidence detector. A single detection event is discarded.

A radioligand that received FDA approval the same day as Pluvicto was Locametz or Gallium (68Ga) gozetotide. This gallium radioligand targets PSMA as does Pluvicto but is only a PET diagnostic agent.

Locametz has 4 carboxylic acid groups, a urea group and two amide groups aiding water solubility and numerous sites for hydrogen bonding of this radioligand to the receptor. The organic portion of the Locametz is called gozetotide, named “acyclic radiometal chelator N,N’-bis [2-hydroxy-5-(carboxyethyl)-benzyl] ethylenediamine-N,N’-diacetic acid (HBED-CC).” The 68Ga (3+) cation is shown within an octahedral complex with a single hexadentate ligand wrapping around it. The short 68 minute half-life of 68Ga requires that a nuclear pharmacy be nearby to prepare it. The short half-life of 68Ga or other positron emitters as well as the possibility of destructive radiolysis to the ligand prevents preparing a large batch and stocking it. Locametz must be synthesized and transported prior to use. This rules out remote or rural hospitals.

Nuclear Chemistry

So, where does one obtain 68Gallium? Well, there are several methods out there. 68Ge/68Ga generators are produced commercially. One company is GeGantTM who offers 1-4 GBq of 68Ga. (Note: 1 GBq is 1,000,000,000 disintegrations per second).

From the scheme above we see the workings of a 68Ga generator. The ligand attachment is performed exterior to the generator. Atomic nuclei that are neutron deficient like 68Germanium can transform a proton to a neutron. There are two ways this can happen. In Electron Capture (EC) an inner “s” electron can be absorbed by a proton converting it to a neutron and emitting a neutrino by the weak nuclear force. This lowers the atomic number by 1, in this case 6832Germanium becomes 6831Gallium. The other mechanism is for the nucleus to emit a positron (anti-electron) and eject 1 positive charge as a positron (and an antineutrino) from the nucleus, resulting in a new neutron. The atomic weight remains constant, but the atomic number drops by one. If available energy in the nucleus is less than about 1 MeV, an electron capture is more favorable than positron emission.

Once you know about the 68Ge electron capture reaction leading to the 68Ga isotope you have to ask, where does the 68Germanium come from? There are a few different ways to make and concentrate 68Ge and the method you use depends on the equipment available to you. One way is to accelerate protons to a high energy in a cyclotron and slam them into atoms heavier than germanium, such as rubidium or molybdenum. The collision with break the target nuclei into pieces by a process called “spallation“.

Cyclotrons

The first cyclotron was independently invented by Ernest Lawrence 1929-1930 at UC Berkeley. It was the first cyclic particle accelerator built. The idea of the cyclic accelerator was first conceived by German physicist Max Steenbeck in 1927. In 1928-1929 Hungarian physicist Leo Szilard filed patent applications for a linear accelerator, cyclotron, and the betatron for accelerating electrons. Unfortunately for both Steenbeck and Szilard, their ideas were never published or patented so word of the ideas were never made public.

Where does one go to get a cyclotron? One company is Best Cyclotron Systems. If you are not sure of how a cyclotron works, check out the image below from Wikipedia. Note: A cyclotron can only accelerate charged particles like protons, electrons, deuterons and alpha particles which are introduced into the middle of the machine. A key component is the “D” or Dee, so-called because of their D-shape. The cyclotron has two hollow, coplanar Dees which are each connected to a high voltage radiofrequency generator. The Dees are open chamber-shaped electrodes that alternately cycle through positive and negative high voltage attracting and repelling charged particles under the influence of a powerful magnet. Because charged particles change their trajectory under the influence of a magnetic field, the particles follow a curved path of increasing diameter, accelerating until they exit the Dees and careen into the target.

First, the word is out. According to the EIA, the US was the world’s leading oil producer for the 6th straight year in 2023 producing 12.6 million barrels per day.

It is common for people to blame rising US gasoline and diesel prices only on restrictions in crude oil production and alleged government regulatory overreach. Indeed, pressure on the gas and oil supply side or even just the threat of it can lea to unstable retail gasoline and diesel prices. What is less appreciated is the role of petroleum refineries on prices. To be sure, there is always price speculation on both the wholesale and retail sides of gas and diesel pricing to consider no matter the throughput. Like everywhere else, sellers in the petroleum value chain seek to charge as much as they possibly can 24/7/365. Everyone is itching to charge more but are hindered by competition and risk.

Refineries are only one of several bottlenecks in the gasoline and diesel supply chain that can influence retail prices. In principle, more gas and oil can always be produced at the wellhead by increased exploration or increased imports. Even so, there are constraints on transporting crude to refineries. Pipelines have flow rate limitations and storage tank farms and ocean tanker fleets all have finite capacity. Another bottleneck today is access to both the Suez and Panama canals. Suez Canal traffic is threatened by Houthi missile strikes on commercial shipping in the Red Sea and the Panama Canal seems to be drying up. The result is increased shipping costs and delays for international transport which the consumer will have to bear.

What do refineries do?

Refineries are very special places. Within the refinery there is 24/7 continuous flow of large volumes of highly flammable liquids and gases that are subjected to extreme temperatures and pressures for distillation, cracking, alkylates, hydrogenations and reformates. The whole refinery is designed, built and operated to produce the fastest and highest output of the most valuable group of products- fuels. This group would include gasoline, diesel, aviation fuel, and heating oil.

Petrochemicals account for approximately 17 % or refinery output. These petrochemical streams account for pharmaceutical raw materials, polymer products, coatings and films, synthetic fibers, personal hygiene products, synthetic rubber, lubricating grease and oils, paint, cleaning products and more. Regardless of what we may think of plastics and other synthetic materials, the 17 % produced by refineries feeds a very large fraction of the global economy. If plastic bags went away overnight, the whole world would begin to search immediately for alternatives like wood, metal or cotton/wool/flax/hemp.

Occasionally technological challenges confront refineries. An early challenge was the production of high octane anti-knock gasoline. This was investigated thoroughly as early as the 1920’s as the demand for more powerful automotive and aircraft engines was rising. Luckily for the USA, UK, and Germany, the anti-knock problem was solved just prior to WWII. This breakthrough led to aircraft engines with substantially increased power per pound of engine weight.

Leaded Gas

The petroleum that goes into gasoline is naturally rich in a broad range of straight chain hydrocarbon molecules. Straight chain hydrocarbons were used in the early days of happy motoring, but the engine power remained low. While these straight chain hydrocarbons have valuable heat content for combustion, the problem with these molecules is that in a piston engine, they cannot withstand the pressures in the compression stroke that would give greater power. To get maximum power from a gasoline engine, it is desirable to have the piston move up and down as far as possible for maximum power delivery to the crankshaft. However, a long stroke length means greater compression and higher pressure near the top of the compression stroke. Straight chain hydrocarbons could not withstand the higher pressures coming from the compression stroke and would detonate prior to reaching top of the cycle. This effect results in knocking or destructive pre-detonation with power loss.

Tetraethyllead was invented in 1921 by Thomas Midgley, Jr, working at General Motors. After some deadly and dissatisfying work by DuPont, General Motors and Standard Oil Company of New Jersey started the Ethyl Gasoline Corporation in 1924, later called Ethyl Corporation, and began to produce and market tetraethyllead. Within months of startup, the new company was faced with cases of lead poisoning, hallucinations, insanity and fatalities.

The first commercially successful fuel treatment to prevent this pre-detonation was tetraethyllead, (C2H5)4Pb, produced by Ethyl. This is the lead in “leaded” gasoline. The use of (C2H5)4Pb began before WWII and just in time to allow high compression aircraft engines to be built for the war. It allowed for higher powered aircraft engines and higher speeds for the allies which were applied successfully to aerial warfare. The downside of (C2H5)4Pb was the lead pollution it caused. Tetraethyllead is comprised of two chemical features- lead and 4 tetrahedrally arranged ethyl hydrocarbon groups. The purpose of the 4 ethyl groups (C2H5) on (C2H5)4Pb was their ability to give hydrocarbon solubility to a lead atom. It was the lead that was the active feature of (C2H5)4Pb that brought the octane boosting property. At relatively low temperature the ethyl groups would cleave from the lead leaving behind a lead radical, Pb., which would quench the combustion process just enough to allow the compression cycle to complete and the spark plug to ignite the mixture as desired.

While tetraethyllead was especially toxic to children, it was also quite hazardous to (C2H5)4Pb production workers. Its replacement was only a matter of time.

Fuel additives were found that would reduce engine fouling by scavenging the lead as PbCl2 or PbBr2 which would follow the exhaust out of the cylinder. While this was an engineering success, it released volatile lead products into the atmosphere.

Eventually it was found that branched hydrocarbons could effectively inhibit engine knock or pre-detonation and could replace (C2H5)4Pb … which it did. While lead additives have been banned for some time from automotive use, general aviation has been allowed to continue with leaded aviation gas (avgas) in light piston engine aircraft like 100 octane low lead (100LL). Only recently has leaded avgas become a matter of public concern.

A refinery not only engineers the production of fuel components, it must also formulate blends for their customers, the gas stations, to sell. The formulations will vary with the season and the location. Some gasolines have ethanol, other oxygenates like MTBE, octane boosters, detergents and more. One parameter is the volatility of the fuel. When injected into the cylinder, it must evaporate at some optimum rate for best fuel efficiency. This will depend on the vapor pressures of the components.

Back to Refineries

The production volumes of the individual fuel products will not match the contents of the crude oil input. Gasoline is the most valuable product, but more gasoline leaves the refinery than arrives in the crude. Any given grade of gasoline has many, many components and the bulk of them have somewhere around 8 carbon atoms in the hydrocarbon chain. Wouldn’t it be nice if longer hydrocarbon chains could be broken into smaller chains to be added into the gasoline mix? And guess what, that is done by a process called “cracking”. A piece of equipment called a “cat cracker” uses a solid ceramic catalyst through which hot hydrocarbon gases pass and get cut into smaller fragments.

But what about straight chain hydrocarbon molecules? Wouldn’t it be nice to “reform” them into better and higher octane automotive fuels? There is a process that uses a “reformer” to rearrange hydrocarbon fuels to give better performance. The products from this process are called reformates.

Reforming is a process that produces branched, higher-octane hydrocarbons for inclusion in gasoline product. Happily, it turns out that gasoline with branched hydrocarbons are able to resist pre-detonation and have come to replace tetraethyllead in automotive fuels entirely. Today we still refer to this lead free gasoline product as “unleaded”.

Octane and Cetane Ratings

Octane rating is a measure of resistance to pre-detonation and is determined quantitatively by a single-cylinder variable compression ratio test engine. Several octane rating systems are in use. RON, the Research Octane Number, is based on the comparison of a test fuel with a blend of standard hydrocarbons. The MON system, Motor Octane Number, covers a broader range of conditions than the RON method. It uses preheated fuel, variable ignition timing and higher engine rpm than RON.

Some gasoline is rated in the (R + M)/2 method which is the just average of the RON and MON values.

In both the RON and MON systems, the straight chain hydrocarbon standards are n-heptane which is given an octane rating of 0 and the branched hydrocarbon 2,2,4-trimethylpentane, or isooctane, which is given an octane rating of 100.

Tetraethyllead and branched hydrocarbons are octane boosters. Methyl tert-Butyl Ether (MTBE), ethyl tert-butyl ether, and aromatics like toluene are also used to boost octane values. Internal combustion engines are built to use a gasoline with a minimum octane rating for efficient operation. A rating of 85 or 87 are often the octane ratings of common “unleaded” gasoline. Higher compression ratio engines require higher octane fuel- premium grade -to avoid knocking.

For comparison, diesel has a RON rating of 15-25 octane so it is entirely unsuitable for gasoline engines. Diesel has its own system called the Cetane rating. The Cetane Number is an indicator of the combustion speed of the diesel and the compression needed for ignition. Diesel engines use compression for ignition unlike gasoline engines which use a spark. Cetane is n-hexadecane which is a 16-carbon straight chain with no branching. Cetane is given a Cetane Number (CN) of 100. Similar to the Octane rating, the branched 16-carbon hydrocarbon heptamethylnonane, or isocetane, is given a CN of 15. Included in the Cetane number.

Refineries must keep close tabs on seasonal demand for their various cetane and octane-rated products as well as the composition of the crude oil inputs which can vary. Each gasoline product stream has performance specifications for each grade. While gasoline is a refined product free from water, most sulfur and solid contaminants, it is not chemically pure. It is a product that contains a large variety of individual hydrocarbon components varying by chain length, branching, linear vs cyclic, saturated vs unsaturated members that together afford the desired properties.

Specific Energy Content

Absent ethanol, the combustion energy values of the various hydrocarbon grades are so similar as to be negligeable. The energy content of pure ethanol is about 33 % lower than gasoline. Any energy differences would be due to subtle differences in blending to achieve the desired octane rating or proprietary additives like detergents. A vehicle designed to run on 85 octane will not receive a significant boost in power with 95 octane unless it is designed to operate on higher octane fuel.

From the Table above and looking at the polypropylene (PP) and polyethylene (PE) entries then comparing to gasoline, we see that the specific energies are the same. The two polymers and gasoline are saturated, hydrocarbons so it is no wonder they have the same specific energies. Polystyrene is a bit lower in specific energy because the hydrogen content is lower, reducing the amount of exothermic H2O formation as it burns. The point is that by throwing away millions of tons of PP or PE every year, we are throwing away a whopping amount of potential fuel for combustion and electrical energy generation.

Petroleum based liquid fuels burn readily because of their high vapor pressure and low flash points. Polyolefins like PP and PE by contrast have virtually no vapor pressure at room temperature and consequently are difficult to ignite. In order to burn, polyolefins need to be thermally cracked to small volatile fragments in order to provide enough combustible vapor for sustained combustion. Plastic fires tend to have an awful smell and dark smoke because the flame does a poor job of energizing further decomposition to vapor.

Going from E10 to E85, the specific energy density drops considerably from 43.54 to 33.1 MegaJoules per kilogram (MJ/kg). Replacing a significant quantity of gasoline with the already partially oxidized ethanol lowers the potential energy. In the tan colored section, we can see the elements silicon to sodium. These elements are either very oxophilic or electropositive and release considerable heat when oxidizing. Some metals amount to a very compact source of readily oxidizable electrons.

Refinery Troubles

According to the US Energy Information Agency (EIA) US refinery output in the first quarter of 2024 has dropped overall by 11 % and has fallen as low as 81 % utilization. Decreasing inventories are causing rising retail prices. Still, average gasoline and diesel prices are currently below the same time period in 2023.

According to EIA, the US Gulf Coast has seen the largest 4-week average drop in refinery utilization at 14 % since January, 2024. This is attributed in part to the early start of maintenance shutdowns of Motiva Port Arthur and Marathon Galveston Bay refineries which account for 7 % of US capacity.

Weather has factored-in this year as refinery production was halted in several locations in the US. A severe winter storm shut down the TotalEnergies’ 238,000 barrel-per-day refinery in Port Arthur, Texas.

Oil production in North Dakota fell to half. Oil production was estimated to have fallen between 600,000 and 650,000 barrels per day.

Exxon Mobil Corp returned a fluidic catalytic cracker and a coker to normal operation at its 564,440 barrel per day refinery in Baytown, Texas.

A Flint Hills Resources 343,000 barrel per day refinery in Corpus Christi, Texas, was significantly impacted by unseasonably cold weather including freezing rain.

The largest refinery in the Midwest, BP’s 435,000 barrel per day refinery in Whiting, Indiana, was taken off-line by a power outage and forced a 10 % drop in refinery utilization in the Midwest the first week in January. Normally the Midwest region produces as much gasoline and diesel as it consumes. This rich local supply leads to somewhat lower prices in the region.

As I bumble and tumble through the chemical literature I frequently run into interesting chemicals and chemistry. Today’s moment of chemistry is with the “Wine Lactone”, so called because it is found in, well, wine. Interestingly it was first identified in koala urine. I saw that this was an opportunity also to dissect the chemical name of the Wine Lactone and perhaps answer questions that you didn’t know you had.

There are numerous forms of the wine lactone that have seemingly minor differences but have different odors. Some of the other “forms” are called stereoisomers and others positional isomers. The atomic composition is the same, but the atoms and their bonds are arranged in a slightly different way. It is not uncommon for these differences to result in a change to the odor or some other property.

The problem with chemical names (nomenclature) for people outside of chemistry is that they seem to be over-complicated polysyllabic tongue twisters with numbers and sometimes Greek letters that are impossible to pronounce or remember. Indeed, they are very often complex and seem to have a mysterious origin. This is where chemistry has strayed away from medieval naming “habits” and supplanted it with a systematic naming system that describes the exact atomic composition, how the atoms are connected and, if necessary, the particular shape in three dimensions.

For thoroughness I’ll point out the molecular formula style like CxHyNzOt where x y, z and t are variable numbers. Other elements were left out for convenient description here. Any organic molecule can be described by the numbers of carbon, hydrogen, nitrogen, oxygen and other atoms present. While the molecular formula is an accurate representation and is necessary for calculating molecular weight, as a unique identifier it is not very useful. Any given polyatomic molecule may have more than one structure that fits the molecular formula.

There are several groups that have been influential in chemical databases and nomenclature around the world. German chemists were on top of this early on with the German language Beilstein database and system of nomenclature (1881) for organic substances, now maintained by Elsevier Information Systems in Frankfurt. For inorganic and organometallic substances, there is the Gmelin database (1817) which is maintained by Elsevier MDL.

The systematic nomenclatures I will be referring to are IUPAC (International Union of Pure and Applied Chemistry) and CAS (Chemical Abstracts Service) supported by the American Chemical Society. I am unaware of the volume of usage of Beilstein and Gmelin databases today. They appear to be ongoing. Not being a German speaker, I’ll use first CAS then IUPAC in that order of priority. CAS and the few other databases use a numbering system for each unique substance in addition to the name. The CAS registry number, CASRN, is used around the world for authoritative identification of chemical substances. This includes academic R&D, industry, Safety Data Sheets, transportation, emergency response and not just in the USA. CAS also manages the TSCA registry list for EPA.

Many chemicals have names that pre-date systematic modern naming conventions like toluol or methylbenzol (methylbenzene, toluene) or vinegar acid (acetic or ethanoic acid). These older, trivial names are deeply entrenched in common usage and the secret cabal of nomenclature mandarins lets it pass uncontested.

Above is a ball and stick 3-D model of the Wine Lactone and next to it is a diagram of the numbering system for the molecule. While any fool could number the atoms, it takes a special one to make it official. The heading of the graphic gives the IUPAC name of the lactone as done by a chemical graphics application called ChemSketch. For comparison, the CAS name is given as well. The CAS database entry for the structure gives a very slightly different version of the same thing.

R&S designations can be omitted if they are not known. Adding R&S to the structure gives a spatially accurate view. It is not uncommon for a structure to be disclosed and given a CASRN before any R or S features are known.

The starting point for assigning a name is to decide what the core structure is, noodle through its numbering and then begin identifying the fragments on it. Somebody in the murky depths of time determined that the core structure of the Wine Lactone is a variety of 5-membered ring called a “furanone” (FYUR an own). The C=O (carbonyl, CAR bun eel) part could be in two places so we’ll have to account for that. With non-carbon atoms in the ring, the non-carbon atom is usually given the place number of “1”.

Both CAS and IUPAC have publications on organic ring structures, however in my experience IUPAC does not show the numbering scheme as CAS would. CAS holds a list of all known ring systems.

Question: Why doesn’t sophomore organic chemistry teach CAS nomenclature rather than IUPAC. Answer: I don’t know other than IUPAC has been taught for a good long time and is usually limited to fairly simple molecules in class. I suspect that the professor’s background as well as the textbook content are involved.

Before we go on, we notice that a hexagonal 6-membered ring is attached at two adjacent places to the 5-membered ring. This is a “ring fusion” and fused 6-membered rings are often given the radical “benzo”. So, the core structure is a type of “benzofuranone”. Oh yes, here a radical is a word fragment added to a name to indicate the presence of something.

Starting with oxygen at position 1 we go around the edge of the fused ring skeleton clockwise and attach numbers to the carbon atoms that are not part of the ring fusion. In the graphic above you can see that there were ring atoms that received simple digits. The atoms that make up the fusion are named by taking the number of the atom that precedes it and adding the character “a” to it.

So, what do we know already? We have a benzofuranone with C=O (carbonyl) at position 2. The “one” radical of furanone indicates that the furan ring has a carbonyl group in it.

Next we must account for the way in which the molecule is arranged in 3-dimensions. Carbon atoms need to have 4 bonds (lines) connected to them. If all of the lines are single, the carbon has 4 atoms arranged around it in the shape of a tetrahedron with the attached atoms at the 4 vertices. A wedged line means that the atom at the end is jutting up and out of the plane of the page. Dashed lines indicate that the group on the end is jutting down below the plane of the page, but the artistic license here is that the dases are omitted. Notice that there are 3 wedged lines at positions 3, 3a and7a. The two hydrogen atoms (H) are projecting up out of the page as is the CH3 (methyl) group. This tells us that the two rings are jutting behind the page, so this molecule is not flat but bent. The name of the molecule has to indicate this.

The carbon atoms at 3, 3a, and 7a are called stereocenters because they have molecular handedness. Note that each is connected to four different groups in the molecule. It sounds like crazy talk but it is quite important. We won’t burrow into details here. Suffice it to say that these atoms will have an extra letter to designate what kind of “handedness” they have. R is for rectus meaning right-handed and S is for sinister meaning left-handed. There are rules for determining R vs S which we will not go into here.

Handedness in a molecule isn’t important except in how they interact with other molecules with handedness. The two nonsuperimposable (chiral) mirror images are said to be “enantiomers” (eh NAN tee oh mers). This is an issue for crystal structure and for many biomolecules. Outside of this, it isn’t much of a concern.

We now have (3S, 3aS, 7aR) to be plopped into the name. This group is shown in parentheses.

Next, we tackle the “tetrahydro” radical- it indicates 4 more hydrogen atoms are present than what would otherwise not be there. In nomenclature they start with rings that are unsaturated in hydrogen, meaning that the carbon skeleton is not connected to as many hydrogen atoms as it could. The four positions where a single hydrogen has appeared are 3a, 4, 5, 7a on what would otherwise be double bonds. There is one more to account for. The namesake furan molecule would have a double bond at position 3. In this molecule there is a hydrogen atom in place of the double bond, so 3H is added with the CH3 group.

So far we have (3S, 3aS, 7aR) and 3a, 4, 5, 7a-tetrahydro and 2-benzofuranone.

At positions 3 and 6 there are two CH3 or methyl groups. To account for position and the fact there are two of them leads to this part of the name- “3,6-dimethyl-“. Elsewhere in the name we denote the R or S configuration, if any. The CH3 at carbon 6 is flat so it lies in the plane pf the page- it is neither R nor S. But the CH3 at carbon 3 juts out of the page at us rather then pointing downward. It has been given the S configuration.

Putting it all together in the CAS name, the configurations at relevant atoms are given first followed by a hyphen then the hydrogen locations followed by a hyphen then the word “tetrahydro”. After tetrahydro radical and a hyphen, the methyl positions 3,6 are added followed by a hyphen then radical “di” attached to the radical “methyl” followed by a hyphen then the core structure 2(3H)-Benzofuranone. The “2(3H)” feature indicates that the carbonyl is at position 2 and an H is at position 3, indicating that the furan ring is connected by single bonds.

I describe here the name of the Wine Lactone in its extended CAS form rather than the parsed form. If you want to sort numbered chemical names alphabetically, leading digits just complicate the sorting. So if you sort alphabetically by the core structure, you rearrange the name to lead with Benzofuranone followed by the details trailing off in the distance as in the first graphic.

(3S,3aS,7aR)-3a,4,5,7a-tetrahydro-3,6-dimethyl-2(3H)-benzofuranone.

I’m sure that deep within the lower catacombs at Chemical Abstracts in Columbus, OH, there are grizzled old nomenclature wizards who may quibble with my explanations, but let them materialize before me in a puff of smoke and discuss the error of my ways.

Prologue: I want to give my bona fides on appreciation of the “US space program.” For as long as I can remember I have been a space enthusiast. I followed projects Mercury, Gemini, Apollo, Skylab, X-15, Space Shuttle, ISS, Voyager’s 1 & 2, Cassini and others in real time. Even though space publicists mention scientific research, they never go into more than the very least they can get away with for fear of MEGO- My Eyes Glaze Over. To its credit NASA posts annual lists of research papers with links disclosing research results from R&D conducted in the orbital environment. Here is such a list. Much of the research might seem arcane but it is important to realize that the practical value is likely to come later as others incorporate it into their subsequent research and product development. This is how R&D works.

A few words about Elon Musk’s plans on moving mankind to Mars. As everyone knows, Musk is actively engaged in developing space craft large enough, numerous enough and powerful enough to take a great many people to Mars. His stated dream for humanity is to transport a large number of people to the red planet to establish a permanent settlement- a sort of Earth 2.0 for humans. There is even fanciful talk of terraforming Mars for more convenient and safer occupation. This is a colossal job, even for a small world like Mars.

All energy produced and consumed on Mars will be electrical via nuclear energy, solar, or maybe wind (??) generation. Combustion as we know it is out due to the absence of combustible materials and abundant oxygen. Solar power generation will be limited by reduced solar energy shining on Mars and by the practical problem of dust accumulation. Thermoelectric generation from a Radioisotope Thermoelectric Generator (RTG) has been the solution used on many Mars landers and deep space probes.

The best radioisotopes for RTG are alpha emitters. Alpha particles are +2 charged helium nuclei which cause a large amount of ionization over a short distance as it crams its way through matter, stopping in a short distance. Because they lose energy over short distances even in air, alphas require very little shielding, unlike beta and especially gamma radiation.

Betas themselves are easily shielded, but as they decelerate in matter, they can generate radiation called braking radiation, or bremsstrahlung x-rays, which are more penetrating. This is how x-rays are generated in an x-ray tube. Electrons impacting a target like copper generates x-rays. The effect is more pronounced in higher atomic number (high Z) elements like copper, but in low Z materials like plexiglass x-ray generation is much reduced. Consequently, beta emitters are commonly shielded with plexiglass.

The main downside to RTG is the low efficiency in converting thermal energy to electrical energy via the Seebeck effect– about 3-5 % currently according to most sources. So, for every 100 watts of thermal energy production, only 3-5 watts of electrical energy are available. This puts pressure on the supply of scarce radioisotopes.

On the good side of RTGs, they are stable, reliable and long lasting. Waste heat can be used to provide warmth for proper operating temperature in the craft or facility. The Mars lander Curiosity uses 4.8 kg of 238PuO2 to produce 100 watts of electrical power.

The deal with the devil you have to make with RTG power generation is that the best heat generating isotopes in terms of power density (watts/g) also have the shortest half-lives. For instance, 210-Po has a high power density of 140 watts/g but a half-life of only 0.38 years. It undergoes a 5.6 MeV alpha decay directly to stable 206-Pb, emitting a gamma only once in 100,000 alpha decays. Gamma emission poses shielding weight penalties and radiation hazards both in manufacture and operation in space. Even with no humans around, there is still the matter of electronic components that are sensitive to radiation. The more commonly used alpha emitter 238-Pu has a lower power density of 0.54 watts/g but a reasonably lengthy half-life of 87.7 years and minimal shielding requirements.

The background radiation environment in space by itself demands that shielding and radiation hardened electronics be used. Any added radiation from an on-board RTG only compounds the problem. The amount of shielding any given material provides is measured in half-thickness, not “full thickness” and is dependent on the type and energy of the particle. This value is the thickness of a specific material required to reduce the intensity to half of the incident radiation, not the total radiation emerging from the shielding material. This is because scattering can occur within the shielding material contributing to or minimizing the total flux. The point of this is that shielding only attenuates radiation to acceptable levels and not to zero.

238-Pu is a synthetic isotope that must be isolated from other Pu isotopes as well as a dog’s lunch of other elements in spent nuclear fuel or be selectively synthesized by nuclear chemistry. Isotopic separation of 238-Pu from other plutonium isotopes is difficult, slow and not the preferred method of producing it at scale. Nuclear chemistry that provides exclusively 238-Pu from a single transformation as with like 237-Np, offers a more productive route. This allows good old regular, valence-electron chemistry to effect the separation needed.

238-Pu is produced by neutron irradiation of 237-Np producing transient 238-Np with its 2-day half-life and subsequent beta decay to the 238-Pu. Chemical separation of the plutonium from residual neptunium is straightforward but, like all chemistry with radioisotopes, burdened by the need for radiation shielding for safety.

238-Pu is presently in short supply in the US. The Savannah River Site was producing “bulk” 238-Pu but was shut down in 1988. After closing of Savannah, the US purchased 238-Pu from Russia but the word is that Russia is short on it as well. In recent years other sites have been scaling up production where “scaling up” means producing in the several hundred grams to a few kilograms in a campaign.

In the RTG, plutonium is not used in the metallic state but as the oxide which is a ceramic or refractory** material like most heavy metal oxides. The plutonium is oxidized to 238PuO2, pelletized and clad in corrosion resistant iridium. According to NASA, this refractory form of plutonium is resistant to an accidental release in a variety of accident scenarios including Earth reentry and rocket propellant fires.

The Seebeck effect is not the only means of producing electrical energy from radioactive decay heat. The free piston Stirling Radioisotope Generator can use decay heat to drive a piston in a Stirling engine using helium gas as the working fluid. Waste heat is dumped at the cooled end of the engine and the linear reciprocating motion of the free piston is used to generate electrical power in the adjacent alternator.

The electric alternator is similar to the electromagnetic flashlight on the market. It works on the ordinary induction principle buy moving a magnet through a coil. You shake the flashlight to recharge it, causing the internal magnet to move back and forth through a coil. Shake it for 1 minute to get 4 minutes of light. The Stirling radioisotope free piston linear alternator operating in this manner can produce 4 times the electrical power of an RGT.

In 2020 workers Wong and Wilson at the NASA Glenn Research Center reported that they were able to operate a Stirling radioisotope power convertor for 14 years maintenance-free.

Off we go!

Some thought will be needed on screening potential migrants to Mars for age, various physical ailments, dental health, genetic predispositions, sociability and underlying psychological issues. A manic crew member could drive fellow crew members to a murderous rage over time. Such screening has been done with astronauts for a long time. I wonder if choosing to migrate to Mars isn’t a sign of some precarious psychological condition in itself, after all the likelihood of a return to Earth may be slim. It would resemble going to jail in some ways.

Over time, the masses of new Martians living in Muskville will have to decide on what to do with themselves beyond exploratory geology, meteorology and engineering studies of Martian accommodations. Mars is a big, arid and frigid desert with no breathable air. But it may offer a few choices for recreation such as spacesuit hiking and shuffleboard. The outdoor choices will be limited by the Muskvillager’s battery, heating and oxygen supplies as well as ability to get around.

Eventually, all manner of psychological, social and physical maladies will manifest in Muskville and will have to be dealt with. People will spontaneously form cliques eventually giving us-vs-them issues requiring mediation. Unless the New Martian settlers are sterilized, pregnancy is a near certainty. An entire book could be written on complications this would bring. The alternative is to limit the inhabitants to a single gender or to gay individuals- most likely a non-starter.

Death on Mars means that your remains will need to rest somewhere outside the facility. A fresh body will freeze stiff in the Martian cold and remain that way indefinitely. Digging a grave will require energy expenditure and digging tools. Cremation will consume considerable power and may be out of reach.

Something like a hospital with medical supplies and trained staff will have to be present. The few physicians who might be present will be required to be generalists with exceptional diagnostic and surgical skills. A full medicine cabinet to cover a range of maladies will be needed to support this.

As Muskvillagers age out, the range of health problems will widen and require care. Diabetes, cancer, dementia etc. will fade in and people will age and die. This will leave job openings and duties behind which will have to be filled.

In general, the conveniences of modern living will be seriously cut short for the New Martians for a long time. A supply line with Earth that can withstand politics, business failure and war must be maintained.

If I were planning a migration to Mars, I’d worry about maintenance and spare parts for everything. Mechanical things will break. Perhaps an orange-colored Home Depot module will hitched to the back of the lander and sent along with a load of duct tape, assorted bolts and screws, sealant, O-rings, hand tools and cleaning supplies. Don’t forget a few bags of peanut M&Ms.

Wherein I jump to conclusions.

The human capacity for folly knows no bound. Woven in with folly are variable education, emotional inputs and diverse belief systems. The migrants will carry religious and political predispositions that they may or may not reveal in screening for candidates. Friends and relatives on Earth will sicken, age and eventually die but access to a return trip to earth may be severely restricted or effectively impossible.

On reflection, establishing even a modest Mars base will involve large energy inputs. Getting to the surface of Mars with enough reserve propellant for the return trip, the establishment of shelter, oxygen and water supplies are the priorities. Beyond just surviving day-to-day, there is interest in the possibility of putting Martian minerals to use as building materials or even water and oxygen production.

There are indications of frozen water on the surface of Mars in certain limited locations. Where there is water there is the possibility of using electric power to produce oxygen. The hydrogen produced may have utility somewhere but its use for combustion seems unlikely due to the corresponding amount of oxygen needed.

Anywhere you have silicates, aluminates and metal oxides, you have oxygen. Silicon and aluminum both have a strong affinity for oxygen and as such represent a thermodynamic well requiring steep energy inputs for oxygen extraction from minerals. Even worse, many silicates and aluminates are oligomers, chain polymers or network polymers that render them insoluble solids with high melting points. Silicates, aluminates and metal oxides are all comprised of a central atom- silicon, aluminum, or a metal -that are electron deficient by virtue of being connected to oxygen anions. In order to liberate oxide from oxidized silicon, aluminum or a metal, something negatively charged needs to come in and displace the oxide species. Metal oxides like the iron oxides are very often refractory requiring high temperatures to react. Then there is a long list of oxyanions like sulfate, phosphate, hydroxide, chromate, ferrates, molybdates, titanates, tungstates, manganates, etc., each with metal cations. After these there are the polyoxyanions …

The point is that there are a wide variety of oxide species to be found in rock and soil with differing properties. In the end, a negatively charged oxide anion must be oxidized to produce molecular oxygen.

A thermodynamic well resides in a substance where atoms come together to form strong chemical bonds and release a great deal of heat into the surroundings. The same amount of energy that was released is minimally what would be needed to drive the reaction in the reverse direction. This bond forming heat energy is dispersed amongst the large number of surrounding molecules. The heat evolved in forming the original bond produces a high temperature locally, but as it spreads out each succeeding layer of neighboring molecules gets a smaller and smaller share of the original energy. As the bond forming energy release is spread over more and more molecules, the resulting temperature rise of the succeeding layers get smaller and smaller.

Newton’s Law of Cooling says that rate of heat flow is directly proportional to the temperature difference between contacting objects. The greater the temperature difference, the more useful work (heat and work are both energy) that can be done. Large temperature differences transfer large quantities of energy. Low temperature differences result in less energy transferred. As the heat spreads to the surroundings it produces decreasing temperatures as the heat conducts away and the ability to do work diminishes. This constrains the recovery of waste heat.

The diffusion of energy in this manner is what entropy is about- the irreversible loss of energy to the surroundings. If you are tempted to talk about entropy, consider that it has to be consistent with its unit of measure: Entropy, S, equals energy per degree Kelvin or Joules/Kelvin (J/K).

In order to get molecular oxygen from minerals it will require a great deal of energy expenditure per kilogram of oxygen. Not only that but specialized equipment and chemicals. Any oxygen produced will have to purified and compressed into cylinders.

MOXIE

The extraction of molecular oxygen from the abundant carbon dioxide atmosphere seems desirable and has actually been put to the test on Mars. A prototype molecular oxygen generator called MOXIE went to Mars on the Perseverance rover and successfully produced oxygen from carbon dioxide beginning in 2021.

The MOXIE oxygen generator is a solid oxide electrolysis device that operates at 800 oC and uses a stack of scandia stabilized zirconia ceramic electrolyte. An excellent source of information on MOXIE can be found at this Science site.

About 10 % yttria (Y2O3) or scandia (Sc2O3) will prevent the zirconia (Zr2O4) electrolyte from undergoing a phase change that causes the ceramic to fail at high temperature. From personal experience I know that scandia is chosen as a better diluent for zirconia because it allows lower temperature operation than yttria by perhaps 200 oC. The lower operating temperature with scandia allows for better sealing of the cell. High temperature seals are very problematic at these operating temperatures.

The MOXIE electrolysis cell uses a nickel coated cathode for reduction of the CO2, a ceramic zirconia/scandia electrolyte that allows oxygen anions to selectively pass through, and an anode where the anions are oxidized and combine to form O2 where it is captured. MOXIE produced O2 at a rate of 6-8 g/hr while on Mars. The process vents carbon monoxide waste as well as unreacted CO2 at the cathode where it is vented.

A limiting factor in operating MOXIE is the operating voltage across the cathode and anode. Two kinds of chemistry can occur within MOXIE. Carbon dioxide can be reduced to form oxide or carbon, depending on the flow rate of CO2 and the operating voltage. The Nernst voltage, VN, is the minimum voltage necessary to do the chemistry. At about 1.1 volts the cell will reduce CO waste biproduct to carbon on the cathode. This is called “coking”. Carbon formation on the cathode impedes the function of the cathode and reduces the output of the cell. The voltage for coking varies very little with flow rate.

The VN for the desired reduction of CO2 to oxide (O–) and CO at a low flow rate is around 1.0 volts and at high flow rates drops to about 0.95 volts or just a bit lower. So, the “normal” operating voltage range then would be between 1.0 and 1.1 volts to prevent fouling the cathode with coke. The operating voltage window seems a bit narrow. It was found that while a stable operating voltage could be supplied, the resistance of the cell was very sensitive to temperature making stable operation a bit delicate.

Pyrochemistry

Extraction of oxygen from lunar mineral samples has been done previously (below). All of the mineral samples were iron rich and gave yields of 2 to 5 % in the form of water. The samples were from Apollo 17 and consisted of ilmenite (FeTiO3), basalt, soil and volcanic glass. The process uses hydrogen at a reaction temperature of 1050 oC producing H2O. Presumably the water vapor is mixed with hydrogen during and after the reaction. The water can be isolated by simple condensation in the presence of the hydrogen.

Reduction of Ilmenite: FeTiO3 + H2 — > Fe + TiO2 + H2O

by Carlton C. Allen

Lockheed Martin Engineering and Sciences Co.

To use the process described above, high temperature is required for the hydrogen reduction in a refractory vessel. This requires considerable electrical energy input to heat the thermal mass of the vessel and the regolith. Spent material will have to be removed and discarded. Perhaps the heat can be recovered for general facility heating. Oh yes, the recovered water will need to be electrolyzed to produce molecular oxygen and hydrogen. This process will use plenty of electric power as well as for the compressors to store the O2 in pressure bottles. In principle the hydrogen can be recovered for reuse in the hydrogenation vessel.

The above process applied to ilmenite produces metallic iron and titanium dioxide, a white pigment. FYI, ilmenite is a common raw material for high purity titanium dioxide production. It is high purity because the titanium dioxide is prepared from titanium tetrachloride which is isolated by distillation from the ore matrix after fluidized bed chlorination.

The first Martian settlers will have to bring every single thing necessary to live on the planet. That includes launching it and landing it on the surface intact. Landing on Mars is tricky because the atmosphere is too thin to provide much aerobraking. The Martian surface pressure is the same as the Earth’s at 80,000 ft altitude and the temperatures are frigid.

Let’s say we successfully land a crew and set up housekeeping. What are they going to do with their time? These missions are supposed to last about 2 years including a lengthy transit time. They can collect various kinds of data on Martian geology and weather and send it back to earth. Somebody will get publications out of it. Eventually, somebody will decide that there must be other things to do besides geology and meteorology. Naturally there will be much ongoing R&D on the pragmatics of living on a remote Martian outpost in a crowded pressure can.

Eventually, the question of what non-research living will look like. Shelter will need construction from some kind of materials. Every new section of shelter will need to be airtight and equipped with environmental controls, sanitation and power. Bulkheads between sections will need to be in place to isolate calamities.

Support staff will be needed one day to provide critical services and perform facilities maintenance. This would also include medical staff, emergency care, food & sanitary support, electronics and IT support and administrative staff for the inevitable paperwork. The lander will need rocket engineers for upkeep and repairs to assure launch reliability for the return trip. Do rockets exist that can sit for a year fueled and then reliably launch and insert into a trajectory back to Earth? There are many, many problems to be resolved in many areas.

After some period of time, a crime will happen on Mars. It could be petty theft, assault or even murder. Someone will have to be appointed to look after law and order. An astronaut-sheriff, sergeant at arms or just the po-leese. What kind of due process will be available to a suspect in a Martian colony? Guns will be too risky to have in the settlement given that a bullet could pass right through a bad guy and rip through the structure creating a leak.